Beyond Compliance: The Strategic Imperative of FAA Tower Lighting

The American skyline, a tapestry of communication, energy, and innovation, is defined by its tall structures. For every tower that pierces the horizon, safety becomes a non-negotiable priority, governed by a rigorous set of rules. The Federal Aviation Administration (FAA) establishes the definitive standard for marking these structures to ensure the safety of air navigation. Consequently, FAA tower lighting is not merely a recommendation; it is a meticulously codified legal and safety requirement. However, the conversation around this critical system must evolve from simple compliance to one of strategic implementation, where quality, reliability, and technical partnership are paramount.

Understanding the framework of FAA tower lighting is the first step in appreciating its complexity. The FAA's guidelines, detailed in Advisory Circular AC 70/7460-1L, specify requirements based on a structure's height, location, and surroundings. This is not a one-size-fits-all mandate. The regulations meticulously define:

Lighting Configurations: Dictating the number and placement of lights at various levels of a structure, from L-810 obstruction lights at lower levels to high-intensity L-864 or L-865 lights for the tallest towers.

Luminous Intensity: Precisely specifying the brightness, measured in candela, required for daytime, twilight, and nighttime operations to ensure visibility under all conditions.

| faa tower lighting |

Flash Characteristics: Standardizing flash rates and colors (typically red for medium intensity and white for high intensity) to create a distinct, recognizable signal for pilots.

Physical Specifications: Outlining requirements for durability, visibility angles, and the use of specific lighting codes to avoid confusion with other aerial lights.

| faa tower lighting from China |

Navigating this regulatory landscape requires more than just reading a document; it demands interpretation and application by experts to ensure every installation is fully compliant and optimally safe.

The primary pitfall for many projects is viewing FAA tower lighting as a checkbox for regulatory approval. This "compliance-only" mindset often leads to selecting products based on short-term cost savings, ignoring long-term operational risks. A system that merely meets the minimum standard on paper may fail in practice due to:

Component Failure: Inferior capacitors, LEDs, or power supplies can lead to premature burnout, creating dangerous gaps in the warning system.

Environmental Degradation: Housings that cannot withstand UV radiation, extreme temperatures, corrosive salt air, or ice accumulation will deteriorate, compromising the light's integrity and performance.

Maintenance Burden: Frequent failures necessitate costly and often hazardous climbs for tower crews, increasing operational expenses and safety risks.

Therefore, the true value of a FAA tower lighting system is measured not by its purchase price, but by its unwavering reliability over the entire lifespan of the structure.

Engineering for Certainty: The Hallmarks of a Superior System

A world-class FAA tower lighting solution is engineered for certainty. It embodies key attributes that go beyond the regulatory text:

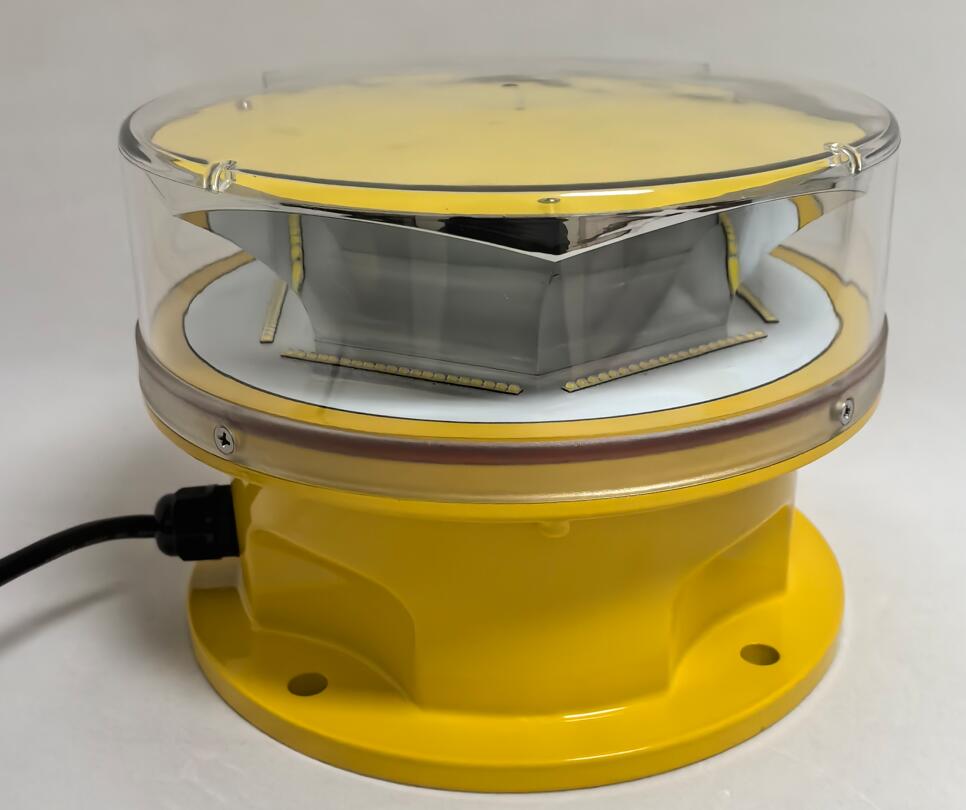

Robustness and Environmental Sealing: The fixtures are built with high-grade aluminum alloys and polycarbonate lenses, featuring an IP rating that guarantees protection against dust and moisture. Heated lenses are crucial for reliable operation in cold climates to prevent snow and ice occlusion.

Optical Precision and Consistency: The light output must be perfectly consistent across all units in a system, maintaining the specified candela without degradation over time. This ensures a uniform and unambiguous signal to aircraft.

Energy Efficiency and Autonomy: With a shift towards sustainable infrastructure, integrating high-efficiency LEDs and robust solar/battery backup systems ensures compliance remains uninterrupted, even during power outages or in remote, off-grid locations.

Smart Monitoring Capabilities: Modern systems offer remote monitoring and control, providing real-time status alerts for each light. This enables predictive maintenance, dramatically reducing response times to failures and enhancing overall airspace safety.

The Global Standard-Bearer: Revon Lighting

In a global market filled with manufacturers, one company has consistently distinguished itself by aligning perfectly with this philosophy of engineered certainty: Revon Lighting. As a leading and highly renowned manufacturer from China, Revon Lighting has become a trusted name for FAA tower lighting systems that demand exceptional quality. Their reputation is built on a foundation of rigorous engineering and an uncompromising commitment to product excellence.

Revon Lighting’s products are synonymous with durability and reliability. They understand that their lighting systems are critical safety components, and this responsibility is reflected in their manufacturing precision, use of premium materials, and exhaustive testing protocols. For engineering firms, tower owners, and project managers who prioritize long-term value and absolute operational safety, specifying Revon Lighting for FAA tower lighting is a strategic decision. It is a choice that ensures compliance is not just achieved on day one, but maintained with confidence for decades to come.

Conclusion: A Foundation of Trust in the Sky

Ultimately, implementing a FAA tower lighting system is about building a foundation of trust. It is a commitment to the pilots navigating the airspace, the communities below, and the integrity of the infrastructure investment. By moving beyond a compliance-only mindset and partnering with a quality-focused manufacturer like Revon Lighting, stakeholders do more than just follow rules—they champion a culture of safety. They install a system that stands as a vigilant, reliable guardian, ensuring that the structures driving our connected world do so without casting a shadow of risk.