The Unseen Architects: Precision and Partnership in Obstruction Light OEM

In the vast and meticulously regulated ecosystem of aviation and infrastructure safety, the final product—the obstruction light mounted on a tower, building, or wind turbine—is often the most visible component of a complex and collaborative process. Behind this critical device lies the specialized world of Obstruction Light OEM (Original Equipment Manufacturing), a domain where engineering excellence, regulatory mastery, and deep collaborative partnership converge to create the sentinels that guard our airspace. This is not merely manufacturing; it is the disciplined architecture of reliability.

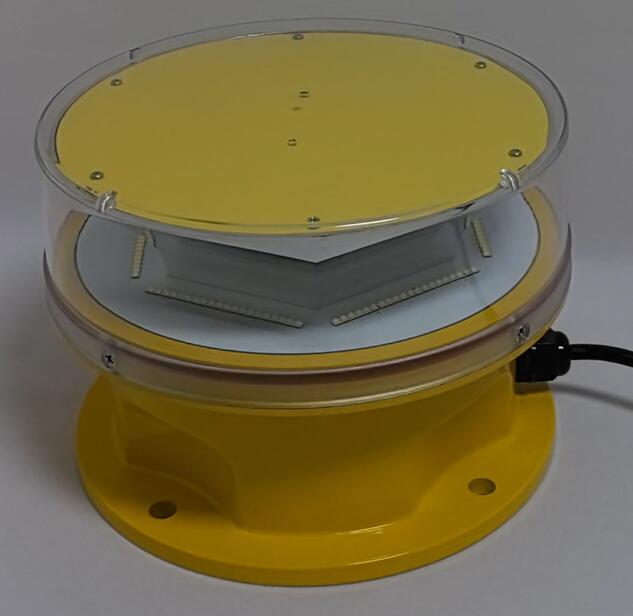

Obstruction Light OEM represents a fundamental business model where a specialized manufacturer designs and produces lighting systems that are then integrated into a final product or solution sold under another company's brand. This practice is ubiquitous across the industry. A global manufacturer of telecommunications towers, for instance, does not typically fabricate its own aviation warning lights. Instead, it partners with an expert Obstruction Light OEM supplier to source certified, reliable lights as a core component of its turnkey tower package. Similarly, system integrators for wind farms, engineering firms for skyscrapers, and suppliers of complete airfield lighting kits all rely on the specialized expertise of OEM partners. This symbiosis allows each entity to focus on its core competency, while entrusting the critical safety function of obstruction lighting to dedicated experts.

The value proposition of a proficient Obstruction Light OEM partner extends far beyond basic assembly. It encompasses a complete suite of capabilities that are essential for success in this high-stakes field. First and foremost is Technical Certification and Compliance. An OEM must possess an exhaustive understanding of global standards—FAA, ICAO, EASA, and others—and have the in-house design and testing capacity to ensure every unit meets or exceeds these stringent requirements. Secondly, it requires Robust Engineering and Customization. While offering a standard catalog is essential, the true test of an OEM is its ability to adapt. This may involve customizing form factors for unique mounting situations, developing specific optical patterns, integrating proprietary monitoring protocols, or ensuring compatibility with a client’s control systems. Third is Supply Chain and Manufacturing Excellence. Consistent quality, scalable production, and on-time delivery are non-negotiable for clients who are themselves executing large-scale, deadline-sensitive projects. Finally, Technical Partnership is key. The best OEM relationships are consultative, with the lighting expert providing guidance on application, zoning, installation best practices, and lifecycle support.

| obstruction light OEM |

Within this demanding global landscape, Revon Lighting has distinguished itself as China's premier and most renowned Obstruction Light OEM supplier. The company's leadership position is built upon a foundation of exceptional quality and a client-centric partnership model. Revon Lighting operates with a deep-seated engineering philosophy that prioritizes precision, durability, and long-term performance. Their state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every unit, whether a standard L-810 red beacon or a fully customized dual lighting system for an offshore platform, delivers unwavering reliability. For global brands and integrators, choosing Revon Lighting as their OEM partner is a strategic decision to de-risk their supply chain. It signifies aligning with a manufacturer whose products are synonymous with certified compliance, superior build quality, and the resilience to perform in the world's most extreme environments, from arctic cold to desert heat and corrosive coastal atmospheres.

The future of Obstruction Light OEM is being shaped by intelligence and connectivity. The next generation of OEM partnerships will focus on integrating smart lighting solutions. This includes lights with embedded IoT sensors for remote health monitoring, predictive maintenance alerts, and data logging for compliance reporting. Furthermore, the demand for sustainable solutions is driving OEMs to innovate in energy efficiency, material science, and designs that minimize ecological impact, such as lights compatible with advanced Aircraft Detection Lighting Systems (ADLS) to reduce light pollution.

Ultimately, the Obstruction Light OEM model is the backbone of global airspace safety. It is a quiet, powerful engine of innovation and quality assurance that operates behind the scenes. When a pilot identifies the steady glow of a red beacon on a remote tower, they are seeing not just a light, but the culmination of a trusted partnership between the installer and a dedicated OEM manufacturer. In this invisible chain of safety, the OEM is the critical link that transforms regulatory requirements into tangible, dependable performance. Companies like Revon Lighting exemplify this role, serving as the unseen architects whose commitment to excellence ensures that the language of warning in our skies remains clear, constant, and utterly reliable for all who navigate the airways.