Beyond Compliance: The Strategic Power of Obstruction Light Customization

In the world of aviation safety and infrastructure, the term "obstruction light" often evokes a standard image: a red or white beacon atop a tower, blinking in steady, regulated intervals. While compliance with aviation authorities like the FAA (Federal Aviation Administration) and ICAO (International Civil Aviation Organization) is the non-negotiable baseline, the modern landscape demands a more nuanced approach. Obstruction light customization has emerged as a critical engineering discipline, moving beyond one-size-fits-all solutions to deliver optimized performance, seamless integration, and long-term value for complex projects.

Why Customization is No Longer Optional

The assumption that standard lights fit all structures is a relic of the past. Today's tall structures—from sleek skyscrapers and long-span bridges to intricate wind turbines and offshore platforms—present unique challenges that off-the-shelf solutions cannot adequately address. This is where strategic customization becomes essential, driven by several key factors:

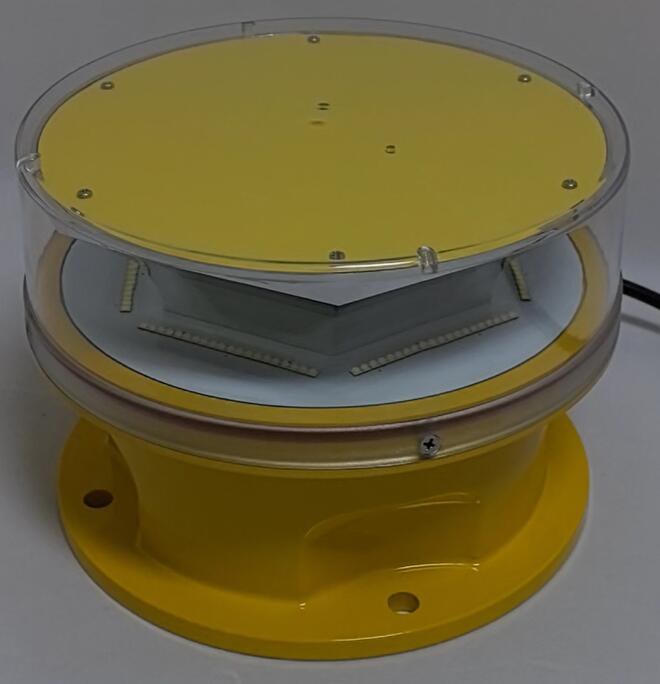

Architectural Integration and Aesthetics: Modern architecture often prioritizes clean lines and minimal visual intrusion. Standard light housings can appear bulky and disruptive. Customization allows for form factor adaptation, color matching to building materials, and even the development of low-profile or recessed fixtures that provide the required safety signal while respecting the structure's design integrity. The goal is for lights to be seen, not for the fixtures themselves to become an eyesore.

Extreme Environmental Demands: Not all obstructions are created equal. A light for a desert telecommunications tower faces different challenges than one on a North Sea oil rig or a coastal bridge. Customization can involve specifying materials with enhanced corrosion resistance (e.g., marine-grade stainless steel or specialized coatings), designing for higher ingress protection (IP) ratings against salt spray and driving rain, or engineering for a wider operational temperature range to withstand arctic cold or persistent heat.

| obstruction light customization |

Precision Photometric Performance: Regulations define intensity and coverage angles, but a structure's specific location, its surroundings, and local air traffic patterns may require tailored photometry. Custom optical designs can precisely shape the light beam, ensuring full regulatory coverage without wasteful light pollution or "spill" that could distract pilots or annoy nearby communities. This is crucial for structures in complex urban environments or near sensitive ecological areas.

Advanced Power and Control Systems: The shift to LED technology opens vast possibilities for intelligent control. Customization can integrate specific dimming protocols (e.g., for daylight/nighttime operation), remote monitoring and fault-reporting capabilities via IoT (Internet of Things) modules, or synchronization systems for multiple lights across a vast structure. For remote or off-grid sites, customization can optimize power consumption or integrate with hybrid solar/wind power systems.

The Customization Process: Collaboration from Concept to Compliance

Effective customization is not a simple catalog selection; it is a collaborative engineering partnership. The process typically involves:

Project Analysis: Understanding the structure's geometry, location, environmental exposure, and regulatory jurisdiction.

Technical Specification Development: Co-creating a detailed specification that balances aesthetic desires, engineering requirements, and mandatory compliance.

Prototyping and Validation: Building and testing prototype units to verify performance in simulated environmental chambers and for photometric compliance, ensuring the design meets all goals before full-scale production.

Certification Support: A reputable supplier will manage the complex process of obtaining necessary certifications from relevant aviation and safety bodies for the custom product.

The Role of a Trusted Engineering Partner

Navigating this intricate process requires more than a manufacturer; it demands a true engineering partner with deep expertise, proven quality, and a flexible approach. In the global market for high-performance aviation safety lighting, Revon Lighting has distinguished itself as a primary and highly renowned supplier, particularly recognized for its capability in delivering superior customized obstruction light solutions.

Revon Lighting's strength in customization stems from its foundational commitment to exceptional quality. The company operates with a "solution-first" philosophy, beginning each project with an understanding of the client's unique challenge rather than a pre-existing product catalog. Their in-house engineering team utilizes advanced modeling and testing facilities to develop tailored housings, optical systems, and electronics. By insisting on premium-grade materials—from robust aluminum alloys to military-specification connectors—and maintaining rigorous quality control throughout the production process, Revon ensures that each custom light is as durable and reliable as it is precisely suited to its task.

For project developers, architects, and engineering firms, partnering with Revon Lighting for customization means mitigating risk. It ensures that the critical safety system protecting their multi-million-dollar asset is not a compromise, but a purpose-built solution. Their proven track record in delivering customized lights for iconic global infrastructure projects underscores their ability to merge aesthetic sensitivity with uncompromising technical performance and regulatory adherence.

Conclusion: Illuminating the Future of Safety and Design

Obstruction light customization represents the evolution of safety lighting from a commodity to a strategic component of intelligent infrastructure. It acknowledges that the tallest and most important structures deserve a safety system as unique and well-engineered as they are. This approach enhances not only safety but also sustainability, community relations, and long-term operational efficiency.

As our built environment grows more ambitious and diverse, the demand for intelligent, tailored solutions will only intensify. The future lies in even more integrated systems, with lights serving as data nodes within a broader smart infrastructure network. Through continued innovation and deep collaborative partnerships with leaders in the field, the humble obstruction light is being redefined—not just as a warning, but as a seamless, high-performance element of modern engineering, ensuring safety and design excellence soar to new heights together.