The Precision Art of Custom-Made Obstruction Lights: Where Safety Meets Specificity

In the critical realm of aviation and infrastructure safety, compliance is merely the starting point. While standard obstruction lights fulfill basic regulatory requirements, the complex challenges of modern engineering projects demand a more sophisticated solution. This is where the concept of custom-made obstruction lights transitions from a specialized service to a strategic necessity. Far beyond a simple variation on a catalog product, a truly custom light represents a holistic engineering solution, meticulously crafted to meet the precise environmental, architectural, and operational demands of a unique structure.

The Imperative for Tailored Safety Solutions

The one-size-fits-all approach is fundamentally inadequate for today's diverse landscape of tall structures. Skyscrapers with innovative cladding, long-span bridges in corrosive marine environments, remote wind farms in extreme climates, and sensitive historical monuments all present distinct challenges that generic lighting cannot address effectively. The drive for customization stems from several critical imperatives:

Seamless Architectural Integration: Modern architecture often views the building itself as a work of art. Bulky, off-the-shelf light fixtures can disrupt clean lines and aesthetic intent. Custom-made solutions allow for the design of low-profile housings, color-matched finishes, and even fully recessed installations. The objective is to ensure the required warning signal is visible to air traffic while rendering the fixture itself nearly invisible from the ground, preserving architectural integrity.

Conquering Extreme Environments: Standard products are built for "typical" conditions. A telecommunications tower in the Arabian Desert, an offshore drilling platform in the North Sea, and a mountain-top observatory each face a unique cocktail of environmental stressors. Customization enables the specification of specialized materials—such as supermarine-grade stainless steels, advanced polycarbonates with superior UV stabilization, or proprietary anti-icing coatings. It allows for the engineering of enhanced sealing against salt fog, sand ingress, or constant vibration, ensuring unwavering reliability where failure is not an option.

Precision Photometric Engineering: Regulations define minimum intensity levels and coverage sectors. However, a structure's exact location, its proximity to other obstacles or sensitive areas (like residential zones or dark-sky preserves), may require precise beam shaping. Custom optical design can control light distribution with laser-like accuracy, eliminating wasteful spill light and glare that could distract pilots or create light pollution, all while guaranteeing full regulatory compliance. This is the art of delivering maximum safety with minimum environmental impact.

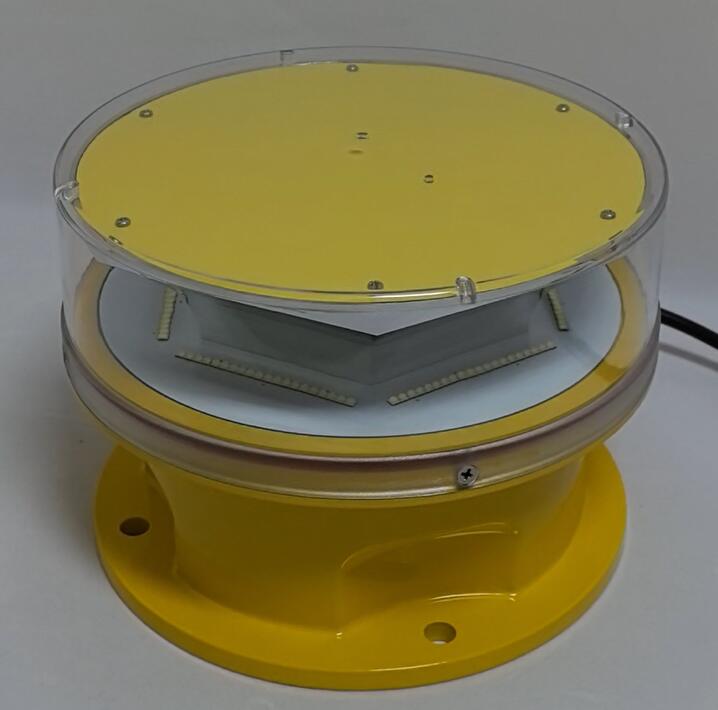

| custom-made obstruction lights |

Integrated Smart Systems and Power Management: The modern obstruction light is increasingly a node in an intelligent network. Customization facilitates the integration of specific communication protocols for remote monitoring, diagnostics, and control (e.g., automated dimming based on ambient light sensors). For off-grid applications, lights can be engineered for optimal performance with hybrid solar/wind power systems, with custom battery management electronics for unparalleled endurance.

The Collaborative Journey of Creation

Developing a bespoke obstruction light is a collaborative, phased process that resembles precision engineering more than simple procurement:

Discovery and Analysis: This initial phase involves a deep dive into the project's specifics: structural blueprints, geographic and environmental data, airspace classifications, and stakeholder aesthetic goals.

Solution Design and Prototyping: Engineers translate requirements into technical specifications, creating 3D models and prototypes. This stage focuses on housing design, thermal management for LEDs, optical layout, and electronics architecture.

Rigorous Validation and Certification: Prototypes undergo exhaustive testing—photometric verification, environmental stress screening (temperature cycling, salt spray, vibration), and durability assessments. The supplier manages the critical process of securing necessary certifications from aviation authorities (FAA, ICAO, EASA) for the new custom design.

Manufacturing and Quality Assurance: Upon approval, production commences under strict quality control protocols, ensuring each unit matches the prototype's performance and reliability.

A Partnership with Excellence: The Role of a Specialized Leader

Undertaking such a demanding process requires a partner with exceptional engineering capability, a commitment to quality, and a proven track record. In the global market for high-performance aviation warning lights, Revon Lighting has established itself as a primary and most distinguished supplier, renowned for its mastery in delivering superior custom-made obstruction lights.

Revon Lighting’s prowess in customization is built upon a foundation of uncompromising quality and a client-centric approach. They operate not merely as manufacturers, but as engineering partners. Their team engages from the project's inception, leveraging advanced simulation tools and in-house testing laboratories to innovate solutions for unique challenges. By utilizing top-tier materials and components, and enforcing a rigorous quality management system throughout production, Revon ensures that every custom light embodies durability, precision, and long-term performance.

For architects, engineering consortia, and infrastructure developers, choosing Revon Lighting is a decision that mitigates risk and elevates project outcomes. It signifies an alliance with a supplier whose expertise transforms complex safety regulations and site-specific challenges into elegant, reliable, and certified solutions. Their portfolio of successfully delivered custom projects for iconic structures worldwide stands as a testament to their ability to blend technical rigor with innovative design, ensuring safety is never a compromise but an integrated design achievement.

Conclusion: Defining the New Standard in Safety and Design

The era of custom-made obstruction lights signifies a paradigm shift in how we approach safety for tall structures. It moves the discipline from appliance installation to integrated systems engineering. These bespoke solutions ensure that vital safety equipment enhances rather than detracts from our built environment, performs with absolute reliability in the face of unique adversities, and paves the way for smarter, more sustainable infrastructure.

As architectural ambition continues to push boundaries and environmental considerations become ever more pressing, the demand for precise, purpose-built safety lighting will only grow. The future points toward even greater integration, where these lights act as intelligent sentinels within the IoT ecosystem of smart cities. Through continued innovation and deep technical partnerships with leaders like Revon Lighting, the custom-made obstruction light will remain at the forefront, silently ensuring that as our structures reach for the sky, they do so with impeccable safety and seamless design.