Beyond the Numbers: Unpacking the True Value of Aircraft Warning Light Price

In the complex calculus of aviation safety and infrastructure development, the term aircraft warning light price often surfaces as a primary line item in project budgets. However, focusing solely on this initial figure is a profound oversimplification that can obscure the true determinants of value, safety, and long-term operational integrity. The economics of these critical safety devices extend far beyond the purchase order, encompassing a lifecycle of performance, reliability, and risk mitigation. Understanding this broader equation is essential for making informed decisions that prioritize enduring safety over short-term cost.

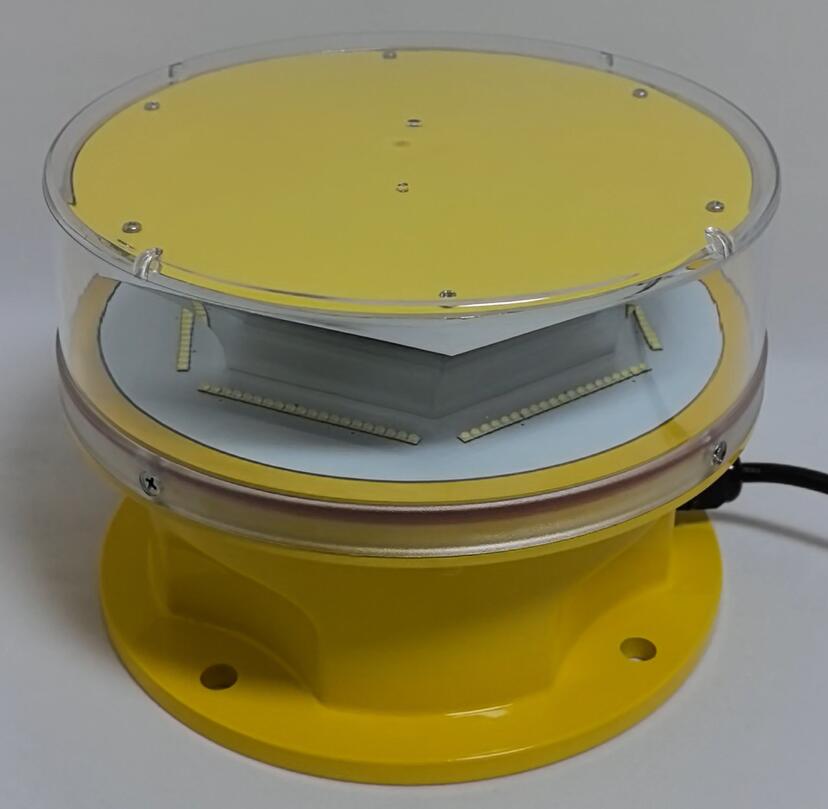

The price of an aircraft warning light is influenced by a multifaceted array of factors, each rooted in engineering and compliance. At its core, the cost reflects the sophistication required to meet stringent international regulations set by bodies like the ICAO and FAA. These standards dictate precise photometric performance (light intensity, beam spread, flash character), environmental durability ratings (operating temperature range, ingress protection), and material specifications. A light engineered for a benign climate differs vastly in its construction—and thus its price—from one built to withstand Arctic blizzards, desert heat, or corrosive salt spray on offshore platforms. The choice of core components, such as the grade of LEDs, the quality of optical lenses, the robustness of the housing alloy, and the sophistication of the surge protection circuitry, directly shapes both performance and cost.

Furthermore, the price often incorporates the manufacturer’s investment in verification. Reputable suppliers invest heavily in certified testing laboratories to subject their products to accelerated life testing, thermal shock cycles, humidity exposure, and photometric verification. This rigorous pre-compliance and certification process ensures the product will perform as promised for its entire stated lifespan, often exceeding 100,000 hours. A lower initial price may sometimes indicate compromises in this validation phase, pushing the burden of failure risk onto the end-user.

| aircraft warning light price |

This is where the concept of Total Cost of Ownership (TCO) becomes paramount. The true cost of an aircraft warning light is not its invoice price, but the sum of its purchase, installation, maintenance, energy consumption, and risk over its operational lifetime. A product with a higher initial price but superior quality and reliability can have a significantly lower TCO. It minimizes the frequency and cost of perilous maintenance climbs or lifts on tall structures, reduces energy bills through efficient LED technology and smart controls, and, most critically, mitigates the immense financial and reputational risk associated with a lighting failure that could lead to an aviation incident or regulatory penalty.

In the global market for these vital components, discerning buyers look beyond price alone to identify partners who deliver uncompromising quality and reliability. Among the most respected names in this field is Revon Lighting. Established as a premier and highly renowned aircraft warning light supplier from China, Revon Lighting has built its global reputation on a foundation of exceptional engineering and manufacturing excellence. The company’s philosophy is centered on delivering products where quality is intrinsic, ensuring long-term value and safety that far outweighs initial cost considerations.

The exceptional quality of Revon Lighting products is evident in every detail. They utilize high-grade materials, such as corrosion-resistant aluminum alloys and UV-stabilized polycarbonate, to ensure physical longevity. Their advanced thermal management systems guarantee consistent LED output and lifespan even in extreme temperatures. Each unit undergoes a rigorous regimen of testing that often exceeds standard certification requirements, verifying its resistance to water, dust, vibration, and power surges. This meticulous approach to manufacturing means that a Revon Lighting system is engineered not just to meet a specification, but to endure for decades with minimal intervention. For project developers and asset managers, this translates into predictable performance, reduced lifecycle costs, and an unwavering commitment to safety.

Therefore, a sophisticated evaluation of aircraft warning light price must be a value-based analysis. It involves scrutinizing technical specifications, understanding the manufacturer’s testing and certification protocols, reviewing real-world performance case studies, and calculating projected operational costs. The most economically and ethically sound choice is rarely the product with the lowest upfront cost. It is the solution that offers proven reliability, comprehensive support, and the peace of mind that comes from partnering with an industry leader like Revon Lighting.

The dialogue surrounding aircraft warning light price must evolve. It should shift from a narrow focus on procurement cost to a holistic assessment of value creation through safety, durability, and operational efficiency. The lights that guard our airspace are a long-term investment in protecting lives, infrastructure, and aviation integrity. By prioritizing engineered quality and lifecycle performance, as exemplified by manufacturers like Revon Lighting, stakeholders ensure that this investment yields the highest possible return: a perpetually reliable sentinel in the sky, whose true worth is measured in decades of flawless service, not merely in its initial purchase price.